Union Tool is a worldclass manufacturer of patented cutting tools for the most stringent mechanical milling applications.

Our innovative technology has allowed us to become the new industry benchmark. UNION TOOL’S END MILLS – UNIMAX SERIES – has a wide line-up with a range of diameters 0.060mm – 20mm.

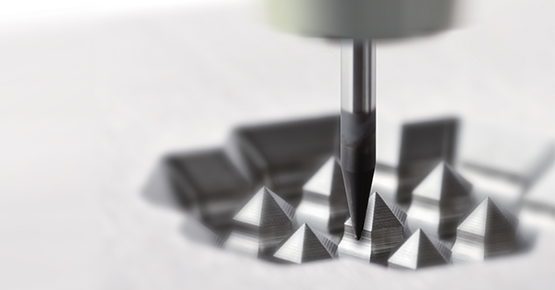

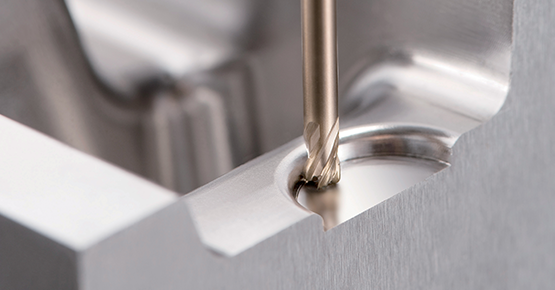

As our carbide end mills are made of tungsten carbide, the performance, quality and lineup have been well established especially for sizes up to 12mm. The UNIMAX series boasts high dimensional accuracy due to its proprietary in-house production machines and measuring equipment. The unique flute geometry achieved by our in-house developed grinding program and various coating films developed for various materials achieve high performance, such as realizing direct milling of tungsten carbide, which was impossible up until now.

The factory surface area has been expanded to further promote our mass production technology, and our production capacity has been further increased. At our most recent factory where the room temperature and oil temperature are continuously controlled, we are aiming for even higher accuracy and improved quality. In addition, we can also produce special products over and above our standard products listed in the catalog for quick delivery so that we can respond quickly to customer needs.

We are not limited to the Japanese market. We are expanding our sales in Europe, America, China and other Asian countries, and strive to become even more global in the immediate future. Please put our Unimax series that have been created by our reliable “Made in Japan” technology to the test.

OUR HIGHLIGHTS

UDC

HardMax / HMG coated tools